시험/측정설비

| |

Testing/Surveying/Measuring equipments |

Features |

|

SEM (Electronic microscope) |

- Magnifies up to 10,000 times any fine defects on the coated surface and the surface structure of other coated areas for observation. |

|

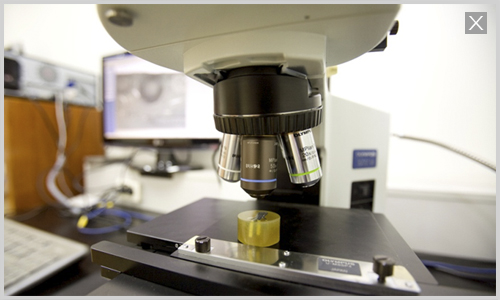

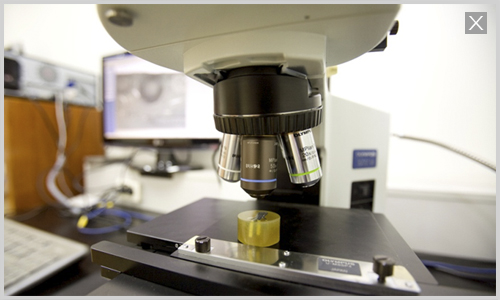

Metal microscope |

- Magnifies up to 1,000 times to determine the causes of surface efects on coated areas. For multiple coatings, the sectional area aids in observation of layered and coating material structures. It can accurately measure metal surface treatment, metal surface and coated area adhesion, and the thickness of each coated area. (This is good for observation of subjects with a high level of horizontality.) |

|

Contact-type microscope |

- Magnifies up to 300 times, similar to a metal microscope. It directly contacts the surface of curved material which is not easily observed through a metal microscope. Useful to check the surface area and defects. |

|

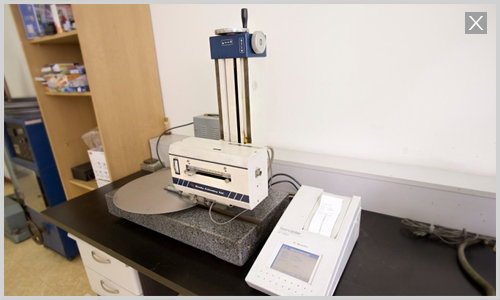

Surface roughness gauge |

- Checks the average roughness of a material and the 10-scale roughness level of a material for coating. As surface roughness greatly influences coated appearance and serves to manipulate coating liquids, it plays an important role in establishing an appropriate roughness level. |

|

Scotch-brite tester |

- Quantifies a coating material’s adhesion resistance A scotch-brite loofah with a certain level of load is rotationally applied to the coated area. The point at which the area is exfoliated will be measured to assess hardness. |

|

Viscosity measurer |

- Measures viscosity, one of the most important coating material actors. Fluid resistance can be quantified by a low or high-viscosity spindle. The thixotropics of a paint can be measured based on a comparison of viscosity according to speed. |

|

Tiger paw tester |

- Tests resistance to scratches and oil, usually applied to cookware products. A transfer with a special scratch testing pen applied is rotated toward a rotating object by a certain angle for a certain length of time to compare and check scratches and exfoliation ( An object is immersed in cooking oil at a temperature of 200℃ to compare oil resistance) |

|

Taber abrasion tester |

- A liquid for coated areas is rotated with a special abrasion wheel used to provide a certain quantity of abrasion to the coated area for a certain length of time to check abrasion levels. |

|

Atlas Cell tester |

- Measures corrosion resistance by consecutively exposing a coated area to 5% brine for a certain period of time. |

|

Brine and soy sauce water boiling tester |

- A test to check corrosion resistance A fluoroethylene resin internal coating material is immersed in 5% brine and 5% soya sauce water for 96 hours to check for any change in status. |

|

PCT tester |

- A test to check steam resistance and adhesion under high temperature and pressure A fluoroethylene resin coated subject is placed under steam a 4 Pressure at 150℃ for 100 to 300 hours to check for any change in status. |

|

Brine spray tester |

- A test to check corrosion resistance coating material is exposed in a 35℃ chamber with a 5% brine mist is maintained. |

|

Basic physical property tester |

- Pencil hardness, cross cutting, drawing, and pin-hole testing. |

|

Gloss Meter |

- Quantitatively measures coated surface gloss. Used for evenly managing gloss level on a coated surface. |

|

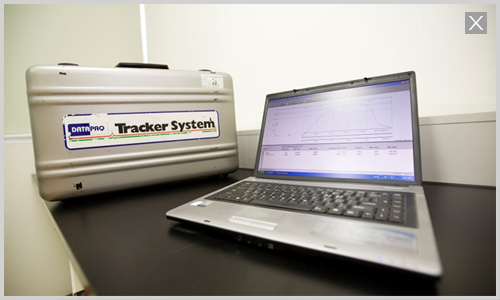

Oven Tracker |

- Checks whether or not a product in a curing tunnel undergoes an accurate curing process by setting the temperature. |

|

Leak Tester |

- Checks vacuum status maintenance or any leakage in a product where vacuum materials are used such as bottles and pots with such properties. |

|

Multi Thickness Meter |

- Checks the thickness of areas coated with steel or non-steel coatings. |